A new separator coating increases lithium–sulphur battery cycle life, addressing rapid degradation and paving the way for lighter, longer-lasting batteries.

Engineers at Norwegian University of Science and Technology (NTNU), have developed a new separator coating for lithium–sulphur batteries, and it’s called HiSep-II. Laboratory results show the coating can extend the cycle life of lithium–sulphur cells from around 200 cycles to about 1,000 cycles. The group filed the patent in 2023 and is seeking industrial partners for commercialisation.

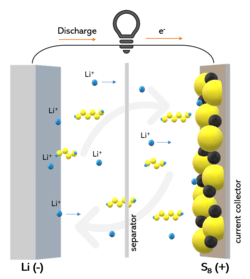

The problem with Lithium–sulphur batteries are, they degrade quickly due to the shuttle effect. In this process, polysulphide compounds are formed inside the LiS battery, causing rapid loss of the amount of charge it can store.

To avoid this, a thin layer of HiSep-II is applied to the separator inside the battery. It acts as a selective barrier, blocking polysulphides while allowing lithium ions to pass. This is designed to slow capacity loss and increase battery longevity.

The new coating can be added during battery manufacturing without requiring changes to the cathode or electrolyte. NTNU reports that using this technology could reduce the weight of an 800-volt electric vehicle battery pack by more than 200 kilograms. Improving efficiency and range for electric vehicles.

Further steps include third-party testing to confirm the coating’s performance under real-world conditions and a range of temperatures. NTNU’s technology transfer office is working to licence HiSep-II for scale-up and market entry.

Lithium–sulphur batteries are attractive due to the abundance and low cost of sulphur, but their commercial use has been limited by short operational life. HiSep-II is intended to address this by targeting the separator, offering a potential solution for longer-lasting and lighter batteries.