AI can find hidden cracks inside machines and buildings in real time, helping prevent accidents and keep industries safe.

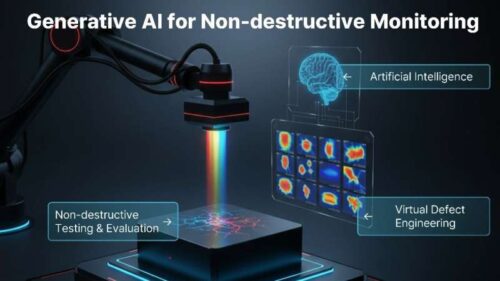

Reliability and safety are crucial in industries like semiconductors, energy, automotive, and steel, where tiny cracks or defects can greatly impact performance. Because these flaws are hidden inside materials, non-destructive testing (NDT) has been used to check their condition without causing damage. Still, accurately detecting and mapping internal defects remains very challenging. Signals from physical sensors, like ultrasonic or electromagnetic waves, are often distorted by factors such as geometry, material properties, and real-world conditions. This makes it inherently difficult to pinpoint the location and size of defects accurately.

But what if artificial intelligence (AI) could “see” what humans cannot? Inspired by this idea, a research team in South Korea from Chung-Ang University have developed DiffectNet. This diffusion-enabled conditional target generation network can create high-fidelity, defect-aware ultrasonic images. Their findings were published on 1 November 2025 in Mechanical Systems and Signal Processing.

By overcoming the limitations of traditional methods, AI can elevate the integrity and safety of industrial systems to a new level. The technology represents a fundamental breakthrough, developing generative AI capable of reconstructing hidden cracks inside structures in real time, surpassing the physical limits of conventional approaches.

Accurate AI detection and reconstruction of internal defects can enable accident prevention, even in environments that are difficult or dangerous for humans to access. In power plants, for example, even a tiny crack can trigger catastrophic accidents. AI-based real-time monitoring allows early warnings of potential anomalies, reducing risk.

In semiconductor and advanced manufacturing facilities, AI can virtually reconstruct internal defects without halting equipment, improving quality control while maintaining productivity. The technology can also be applied to real-time monitoring of infrastructure, such as buildings and bridges, supporting smarter and more resilient urban safety management.

These applications illustrate how AI is enabling engineering capabilities once thought impossible. By acting as the “eyes” of structures, AI opens new possibilities for real-time defect reconstruction and prediction in reliability-critical industries, including aerospace, power generation, semiconductor manufacturing, and civil infrastructure.