As electronics grow more complex, traditional reflow soldering is giving way to a shift promising cleaner joints, stronger reliability, and performance breakthroughs across advanced circuit designs. What is it actually?

reflow system

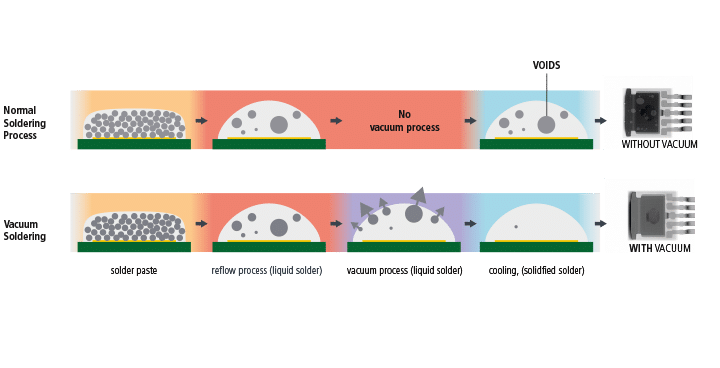

Vacuum reflow soldering technology, although limited in adoption, is emerging as a key focus in high-reliability electronics. While traditional reflow struggles to release trapped gases and form ‘solder voids’ during power density rise, vacuum technology can control this long-standing enemy of joint performance.

In conventional surface-mount technology (SMT), voids can compromise joint strength, reduce heat dissipation, and degrade long-term reliability in high-power applications. Applying a controlled vacuum during the molten phase promotes denser solder joints with improved thermal conductivity and electrical performance. This method also helps joints better withstand thermal cycling, vibration, and mechanical stress, making it suitable for applications such as electric vehicle (EV) power modules, radio frequency (RF) hardware, automotive electronic control units (ECUs), medical devices, and telecom systems.

Originally developed for aerospace and defence, vacuum reflow is increasingly explored for high-value assemblies where joint consistency and reliability are critical. Reducing defects early in the process, it can support smoother production runs and help maintain quality, while also easing downstream inspection and rework requirements.

The process integrates precise thermal profiling with vacuum curves, often using inert gases such as nitrogen to minimise oxidation and ensure proper wetting. Both batch and inline ovens can handle BGAs, QFNs, IGBTs, and fine-pitch components. Real-time monitoring and data logging are used to maintain consistency across complex boards and meet IPC-A-610 and MIL-STD standards. Lower oxygen levels and careful flux control further contribute to uniform, robust solder joints.

“Traditional solder processes often struggle to keep voids consistently low,” says Phil Zarrow from Indium Corporation. “Vacuum reflow can push void rates toward single-digit levels, enabling stronger, more reliable solder joints.”

As circuit miniaturisation, process automation, and Industry 5.0 practices advance, vacuum reflow stands out for its reliable quality and seamless integration into modern production lines. With market forecasts, the technology is seeing notable growth, especially in automotive, telecom, and high‑power industrial applications.

Global vacuum reflow manufacturers

Leading vacuum reflow suppliers / distributors in India