Struggling to measure flow without using much battery power? This ultrasonic module uses low power, measures flow, and can detect small leaks anywhere.

Measuring flow accurately while keeping power use extremely low can be a challenge, especially in battery-powered systems. Detecting leaks or tracking water usage over long periods often requires sensors that are either power-hungry or mechanically complex, limiting their reliability and lifespan.

The UFM-02 ultrasonic flow module from ScioSense addresses this by combining high-precision measurement with ultra-low power consumption. It runs on just 50 µA on average, making it possible for battery-powered devices to operate for years without replacement. Unlike traditional flow sensors, it has no moving parts, reducing the risk of mechanical failure and improving reliability.

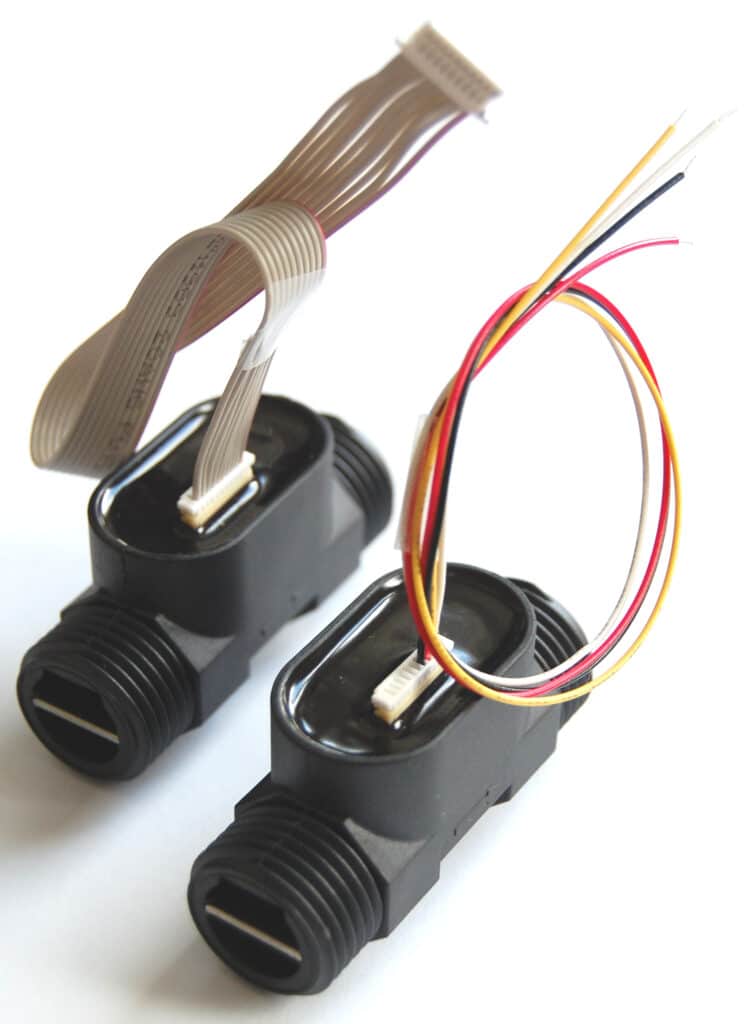

The module is fully calibrated and ready to use, with standard pipe fittings, twin ultrasonic transducers, and a precision measurement circuit based on ScioSense’s ultrasonic flow converter chip.

It is suitable for a wide range of applications: from water purifiers, dispensers, boilers, coffee machines, and smart faucets, to irrigation systems, agricultural equipment, pools, spas, and cooling systems. In industrial and commercial setups, it can track total water volume through filters, allowing replacements based on actual usage rather than fixed schedules.

The ultrasonic measurement technology in the UFM-02 has no turbines or other moving parts. This provides two key benefits:

- Reliable operation and long lifetime, with no risk of mechanical failure.

- High sensitivity to very low flows, allowing accurate leakage detection. In its smallest 3/8” thread size, the UFM-02 can measure flows as slow as 0.03 liters per minute.

Andreas Blocherer, Senior Product Manager at ScioSense, said: ‘The introduction of a truly low-power implementation of ultrasonic flow sensing makes this fantastic technology accessible to a new range of applications. The UFM-02 can be operated on battery power without an external cable connection, which means that flow sensing or leak detection can be implemented anywhere. This enables equipment makers to easily add intelligence about liquid usage to make the system more efficient, reliable or cost-effective.’