High-power induction cookers can cause interference. This reference design shows how you can reduce EMI and make the cooker work and heat properly.

Half-bridge induction cookers are widely used because they can deliver both high- and low-power heating efficiently. However, at high power, the fast switching of IGBTs generates narrow-band electromagnetic interference (EMI), which can disrupt nearby electronic devices. As households increasingly rely on multiple electronic systems, electromagnetic compatibility (EMC) has become a critical concern for engineers designing induction cookers. Consumers expect appliances to operate reliably without affecting other devices, and engineers face the challenge of balancing high power output with low EMI.

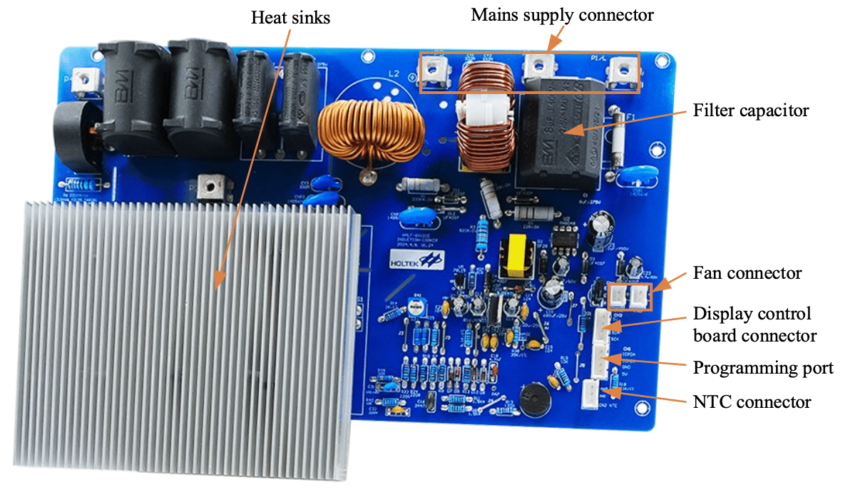

Holtek’s EMC-enhanced half-bridge induction cooker reference design addresses these challenges, providing a framework that design engineers can leverage to improve EMI performance and reliability. The design employs a dual-board structure consisting of a power heating board and a display control board. The display board, managed by the MCU, handles touch input, LED driving, and noise immunity, while communicating with the power heating board via the I2C interface. This separation of control and power allows engineers to isolate noise-sensitive functions and improve system stability.

The power heating board is built around the MCU, a highly integrated controller tailored for half-bridge induction cookers. This MCU features 12-bit complementary PWM outputs with dead-time control, allowing engineers to adapt the outputs to a wide range of IGBTs. It includes nine over-voltage protection (OVP) circuits, which provide AC voltage surge protection, over-current protection for the IGBT and resonance current, LC resonant current and voltage phase detection, and AC voltage zero-cross detection. An integrated OPA circuit amplifies and measures AC current, enabling accurate power calculation. The MCU also supports frequency jittering, a technique that modulates the IGBT switching frequency to reduce peak interference and back voltage, further lowering EMI. Engineers can use these features to protect the system, optimize performance, and simplify adaptation to different hardware configurations.

The reference design incorporates a dedicated EMC circuit that works with frequency jittering to disperse interference energy across a wider spectrum. This functions similarly to a spread spectrum approach, reducing the amplitude of peak EMI signals and improving CE conducted interference margins. For engineers, this means that compliance testing can be achieved more easily, and designs are more robust against electromagnetic noise in real-world environments.

The half-bridge architecture itself provides high reliability and efficient power conversion. Dual IGBT inverter modules handle alternating current positive and negative half-cycles, delivering high current conversion efficiency and reduced losses. In operation, a rectifier converts 50 Hz AC to DC, which passes through an LC resonance circuit and the IGBT switching circuit. This is converted into a 20–50 kHz high-frequency AC current, generating a magnetic field in the induction coil. When cookware is placed on the cooktop, the magnetic field induces eddy currents in the metal base, producing heat efficiently.

Holtek has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.