Struggling to develop wearable health devices fast? See a platform that tracks vital signs, measures sleep and stress, and saves engineers months of design work.

Design engineers face a major challenge when developing wearable health devices: building accurate, reliable sensors from scratch takes months, often delaying product testing and clinical evaluation. Collecting high-quality data for SpO2, ECG, heart rate, and other vital signs while keeping power consumption low adds further complexity.

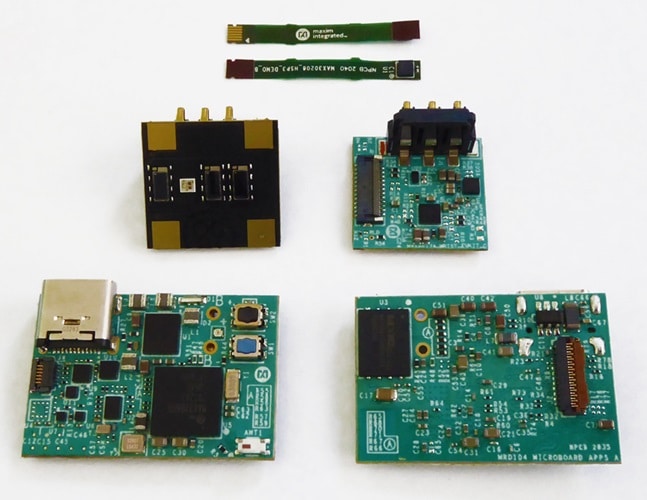

The MAXREFDES104# from the Analog Devices (ADI) addresses these challenges. This third-generation health sensor reference platform lets engineers quickly test and evaluate wearable health products without starting from zero. It tracks blood oxygen saturation (SpO2), ECG, pulse rate, heart rate (HR), body temperature, and motion. Built-in algorithms provide HR, heart-rate variability (HRV), respiration rate (RR), SpO2, body temperature, and analytics like sleep quality and stress—all at clinical-grade accuracy. Engineers can even use it in clinical trials, saving months of development time. The design is flexible, supporting wrist-worn devices, chest patches, or smart rings.

The platform uses a low-noise optical PPG and electrical ECG analog front end (AFE) that delivers 110 dB signal-to-noise ratio (SNR) for SpO2 and over 110 dB common-mode rejection ratio (CMRR) for dry electrode ECG. Engineers can record PPG and ECG simultaneously at different sample rates, enabling pulse transit time measurement for cardiac health applications.

A highly integrated power and battery management IC (PMIC) simplifies design by combining a high-accuracy ModelGauge m5 EZ fuel gauge, haptic driver, and low-noise buck-boost converter. This ensures signal quality while minimizing power use, reducing engineering effort in wearable device development.

Bluetooth-enabled, ultra-low-power microcontrollers with dual Arm Cortex-M4F cores and SmartDMA let BLE run independently, freeing main cores for other tasks. The system also includes security features and memory error-correcting code (ECC) for reliability.

For algorithm development, an ultra-low-power microcontroller handles Maxim’s PPG algorithms for pulse rate, SpO2, HRV, RR, sleep, and stress. It can act as a sensor or algorithm hub, controlling the MAX86176 sensor and providing raw or processed data, reducing design workload.

Finally, a small, low-power digital temperature sensor with 0.1 °C accuracy meets clinical standards while using 33 % less current than alternatives. It can be mounted on a flex cable or PCB, giving engineers flexibility in device layout.

ADI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.